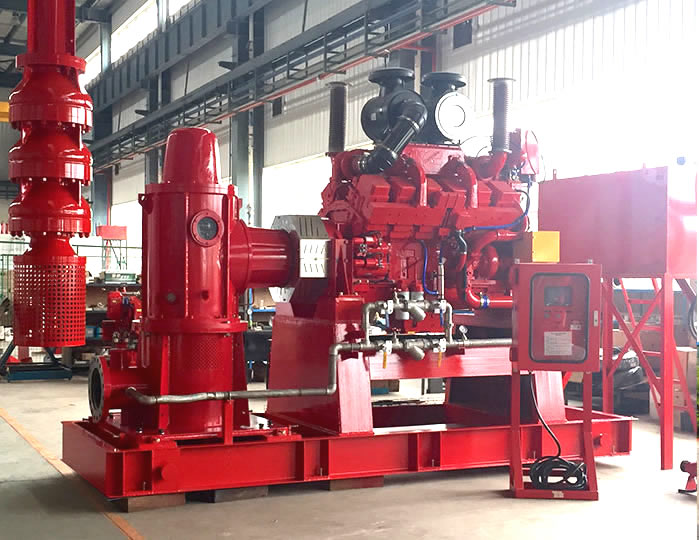

NO1. Vertical Turbine Pump

We have rich experience in producing the vertical turbine pump, and we have exported it to many countries like Malaysia, Russia, Indonesia, Peru, Chile and so on. It iw widely used in transporting clean water and sewage containing certain solid particles (such as iron chips, sand, coal powder, etc.), corrosive industrial wastewater and seawater. The body temperature should not exceed 80 C. It is widely used in raw water treatment plants, sewage treatment plants, metallurgical and iron industry (especially swirling pools in this industry to transport scaled iron oxide water), power plants, mines, municipal works and farmland water conservancy projects. The series of products have been proven to be reliable in performance, stable in operation and could meet the international standards.

NO2. RV-SP Vertical Slurry Pump

RV-SP vertical slurry pump is a single-stage and single-suction vertical centrifugal pump. The fluid flows out along the axis of the pump shaft at 70 degrees. The main components are volute, impeller, pump base, pump shell, support barrel, motor base, etc. It is widely used in landfill pits and coal-water pits in coal washing yards of thermal power plants, discharge of high-concentration coal-bearing slag wastewater, and suction of dense liquids, dirty liquids, pastes, flowing sand and flowing sludge from urban rivers in municipal, chemical, printing and dyeing, medicine, shipbuilding, foundry and food industries and so on.

NO3. PWDDFL Series Submerged Sewage Pumps

PWDDFL series submerged sewage pumps are single-stage and multi-suction vertical centrifugal pumps. The impeller is three single-chord curved blades. The semi-closed impeller is selected and malleable cast iron is used, so it has high strength and corrosion resistance. It is easy to process, good throughput and high efficiency. Three single impeller can play a good role in stirring, replacing the traditional structure of stirring head, reducing the shaft power of the pump, saving the cost of motor matching and electricity. It is widely used in coal pits in coal washery of thermal power plant, leachate catchment pits, discharge of high concentration waste water containing coal slag. It can also be used in municipal, chemical, printing and dyeing, medicine, shipbuilding, foundry, food and other industries to suck thick liquid, dirty liquid, paste, flowing sand and flowing sludge in urban rivers to remove sludge from coal mines. The fluid of small gravel. Waste water containing high concentration of iron oxide scale in iron oxide pit of smelter, etc. The series of products have been proven to be reliable in performance, stable in operation and meet the international standards.

NO4. CCB Series Kitchen Waste Disposal Pumps

The product is mainly used for conveying kitchen waste slurry, waste water, grease and other media. The service life is much longer than that of screw pump and submerged pump. It uses a large pipeline anti-clogging structure, so that the diameter of particles passing through can reach one fourth of the caliber. According to the user's requirement, in the case of no leakage, on the basis of no sealing, it can also be added with a packaged seal. This product is very popular among the food industry and we have provided a lot to government-funded industry.

Applicable working conditions

1. The temperature of the conveying medium is less than 150 C.

2. The solid volume ratio of the medium is less than 25%.

3. The kinematic viscosity of the conveying medium is (7-23)*10-6/s.

4. The density of conveying medium is less than 1800 kg/m.

Structural characteristics

CCB series kitchen waste disposal pump has obvious technical advantages:

1. The impeller of the pump is a semi-open structure, and its efficiency is 10%-15% higher than that of the traditional screw pump and the submerged pump. The power of the distribution motor of the pump with the same performance parameters is generally one grade lower, and the energy saving is remarkable. At the same time, the impeller has good cavitation resistance.

2. The seal adopts multi-side hydrodynamic seal, which consists of auxiliary impeller seal and shutdown seal. It is suitable for frequent start-up occasions.

3. The connection is rigid between pump and motor. Looking down from the motor end, the pump rotates clockwise.

4. The bottom of the pump is designed with a unique settling chamber suitable for kitchen waste disposal operation. The sediment chamber at the bottom of the pump can not be sunk through the outlet of the discharged residue medium, and can be cleaned through the dredging hole.

NO5. H Series Right Angle Gear Box

H series right angle gear box is a horizontal shaft directly connected with the internal combustion engine, horizontal motor, gas turbine and other prime movers. After reducing (or increasing) speed, the power is output from the vertical shaft. It can withstand the axial thrust and transfer the power of the horizontal axis of the prime mover to the vertical pump shaft for transmission and speed change of deep well pump, axial flow pump, oblique flow pump, long shaft pump, submerged pump and other vertical shaft working machines.

Performance and Advantages of H Series Right Angle Gear Box

Various models and transmission ratios can meet the requirements of high and low speed prime movers and working machines. Strong ability to withstand vertical axial forces makes the structure of working machines simplified. H series gearbox has the characteristics of wide application range, economy, high efficiency, space saving and suitable for various climatic conditions.

Application Range of H Series Right Angle Gear Box

It can be widely used in water conservancy engineering, municipal engineering, metallurgical mine, petrochemical industry, fire protection and marine engineering and other fields.

technical parameter

Input speed: 245-3460 rpm

Output speed: 490-3460 rpm

Growth ratio: 1:1-1:2 deceleration ratio: 4:1-11:10

Power: 0-1520HP

Able to withstand maximum axial thrust: 125000N

QQ

QQ